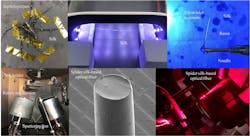

An international team of researchers, led by National Yang Ming Chiao Tung University (NYCU) in Taiwan, has developed a sensor and sensing technique that uses spider silk as optical fiber to detect and measure small changes in a biological solution’s refractive index in real time—including glucose and other types of sugar solutions (see figure above and video below).

Why spider silk? It’s a biocompatible material that can transmit light in a manner similar to optical fibers, has elastic properties, and is also quite sturdy.

This work “is significant to the advancement of point-of-care diagnostic devices, which can give immediate results after monitoring and for diagnosis of certain diseases,” says Cheng-Yang Liu, the team’s leader and a professor in NYCU’s Department of Biomedical Engineering. He adds the new sensor could be particularly beneficial for monitoring glucose levels for those with diabetes, because “the sugar sensor we fabricated is practical, compact, biocompatible, cost-effective, and highly sensitive.”

In the study, the researchers harvested the silk, with a diameter of about 10 µm, from a type of giant wood spider, Nephila pilipes, native to Taiwan. They coated the spider silk with a fine nanolayer of metal to enhance its sensitivity. Then, they encased it in a biocompatible, photocurable resin to create a 100-µm-diameter fiber optic structure, inside which the spider silk acts as the core and the resin acts as the cladding.

One end of the fiber structure was immersed in liquid resin and the other end connected to a light source and spectrometer. The light intensity spectra created by the new sensor was compared with refractive index measurements, which allows the researchers to detect the type of sugar and its concentration.

“In the future, we hope this silk-based fiber-optic sugar sensor can exist as one of the medical devices in point-of-care diagnostics and testing,” Liu says.

Towards clinical application

The team is working to improve the accuracy and quality of the new sensor, which will be crucial before it can be used in a clinical setting. Enhancing the sensitivity of the device to adapt to environmental changes, such as pH value, will also be key.

They also plan to extend the new sensor’s functionality to measure biochemical components in the human blood, such as lactose and fat, and find their proportions. “We hope this sensing device can used in the heart, brain, and the respiratory tract,” Liu says, and a database from the data spectrum obtained from each measurement could be developed and paired with mobile devices “so that it can be readily read anytime and anywhere.”

“With further development,” Liu adds, “we also hope it can be used in implantable medical devices and treatment strategies in biomedical applications.”